FREEDOM OF

MOVEMENT

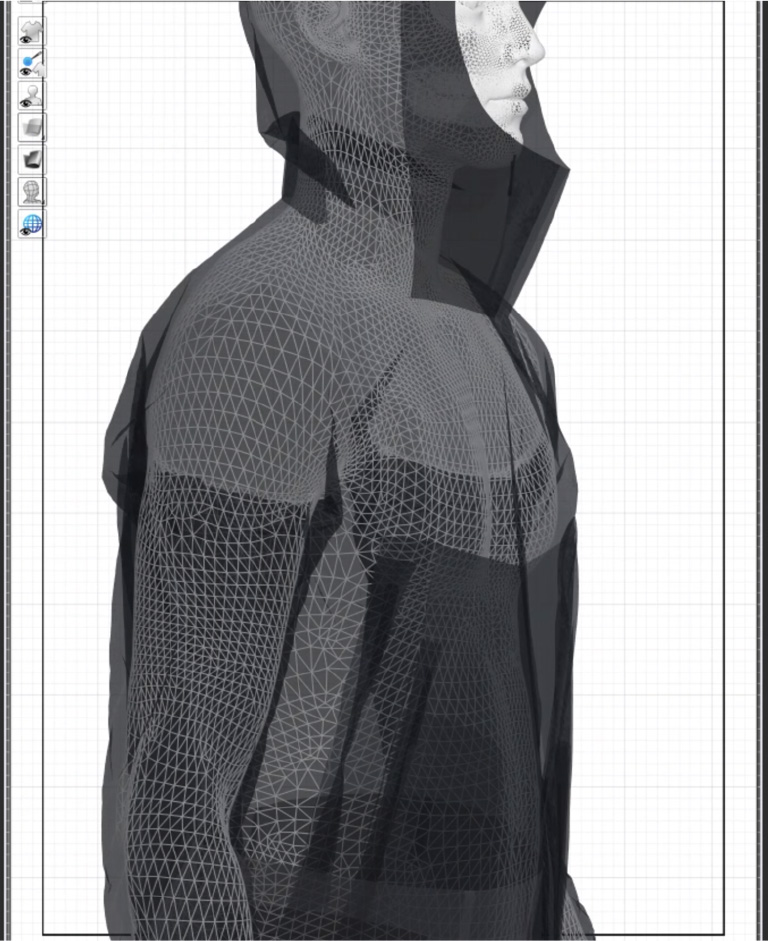

ERGONOMIC 3-DIMENSIONAL PATTERNING

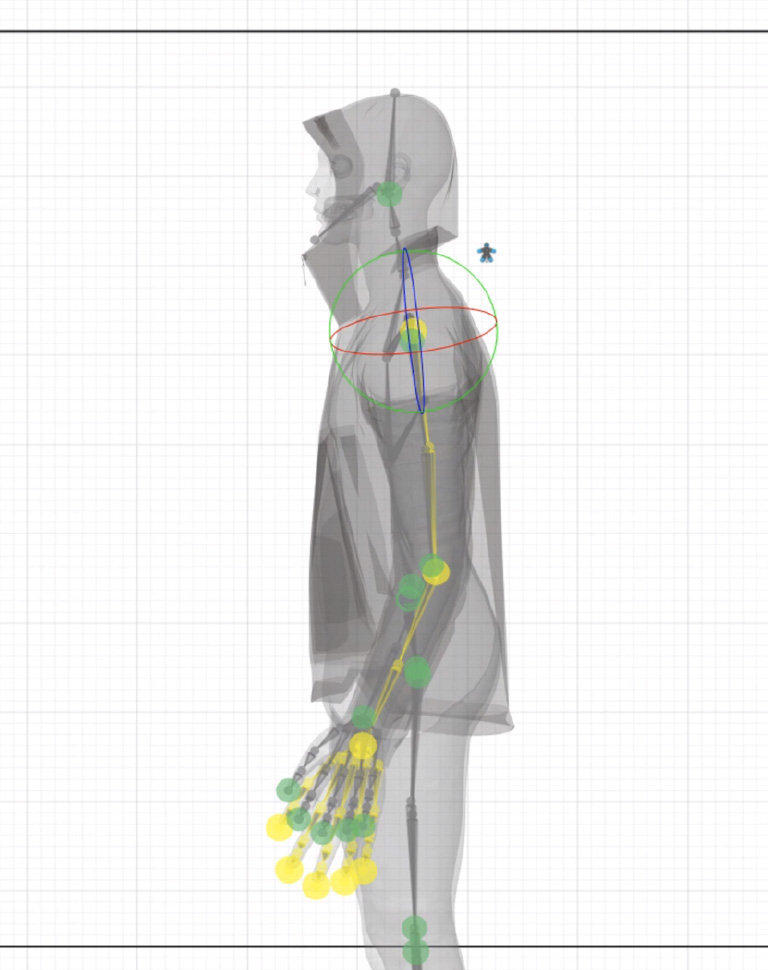

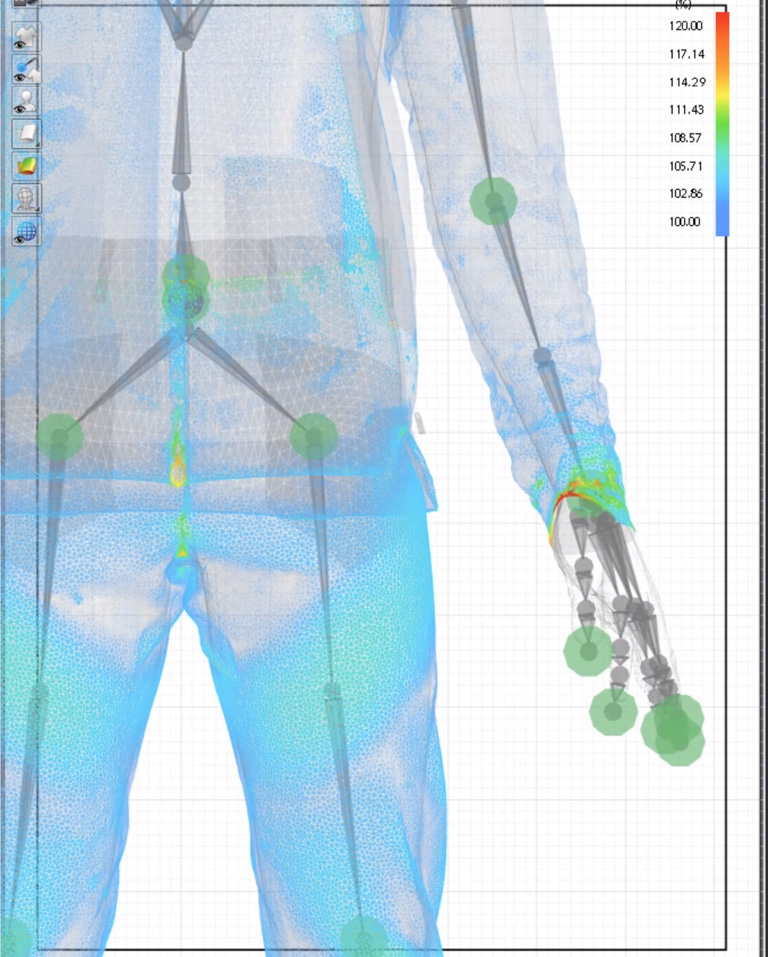

Ergonomic 3-Dimensional Patterning (E3D) refers to the advanced gusseting and articulation in our garment patterning that creates the widest range of motion in key, often overlooked areas. Garments patterned under this technology allow the wearer to move freely, unrestrained by their clothing.

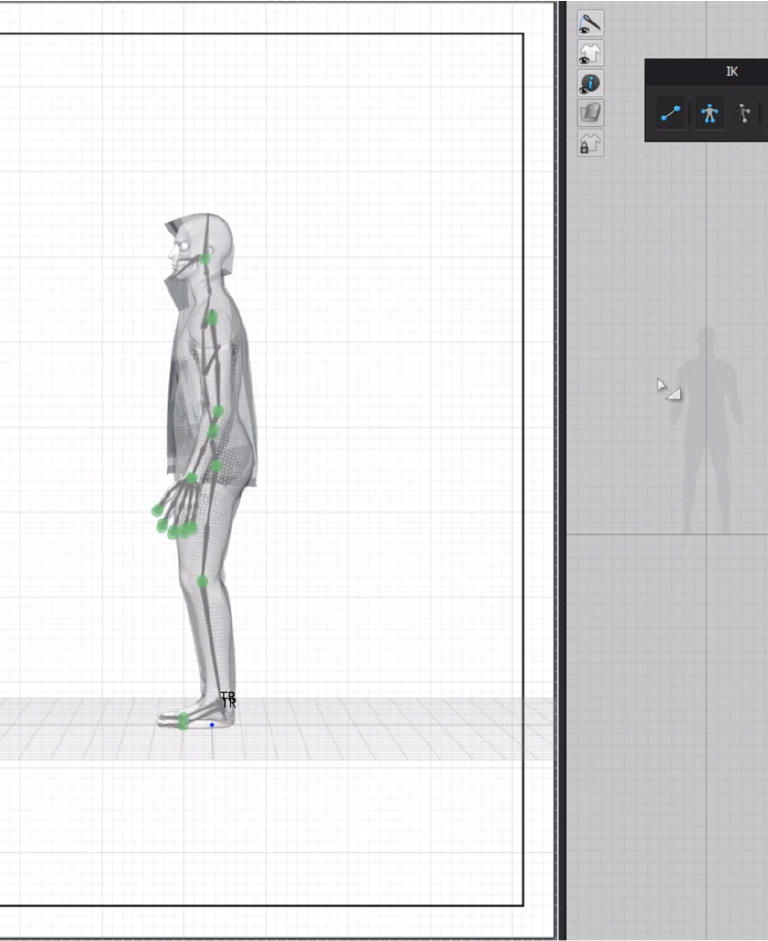

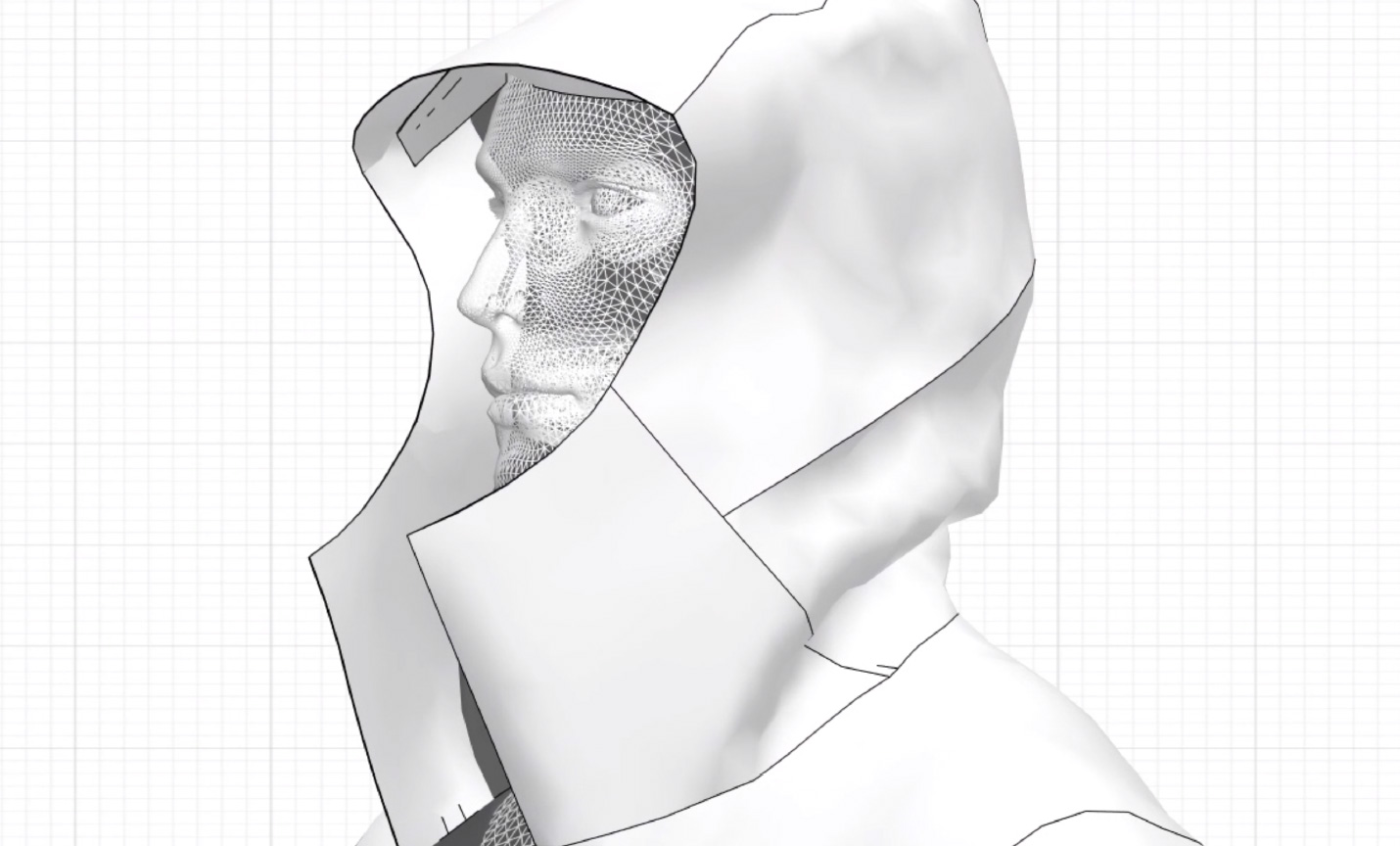

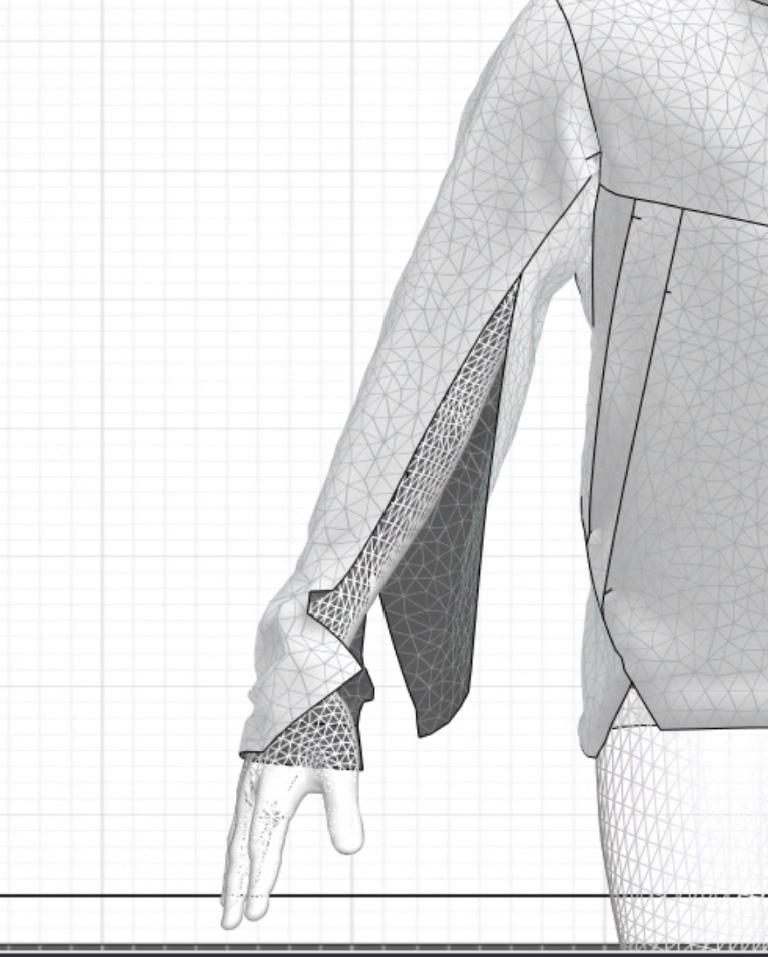

Combining advanced material application and innovative construction methods, E3D enhances speed, efficiency, and accuracy in our design and development process. Rather than drafting in 2D and waiting to produce samples in order to view the initial form, our designers begin by digitally assessing the overall fit, understanding how the material drapes and moves on the body.

Combining advanced material application and innovative construction methods, E3D enhances speed, efficiency, and accuracy in our design and development process.

We can see the enhanced user experience demonstrated best on our proprietary underarm gusset. When the arms are raised in a traditionally structured garment, the hem also rises, exposing the lower torso to cold conditions. The E3D pattern allows the jacket to sit naturally when the arms are down, and remain intact through a wide range of motion.

E3D has allowed our designers to experiment at a level that wouldn’t be possible in a more traditional environment, and maintain complete ownership through the ideation to manufacturing process. It is common practice for designers to send their sketch and specs to a factory, who in turn creates the pattern, produces a sample, and returns it back for the revision process to begin. Not only has retaining these steps in-house significantly reduced the production of unnecessary samples and preserved materials, it has allowed us to continue hands-on design in a time when physical distancing, factory closures, and shipping delays have obstructed many businesses.